|

WELCOME to Heat Treatment Service

Short Description:

Heat transfer takes place by radiation only in vacuum, which is ineffective at lower than 500 oC and develop large temperature difference between surface and core of work piece.

Such temperature difference should make thermal stress, which might cause some distortion of work piece.

Heat treatment of components with heat.

Tool steel, high mix

- hardened tool steel, high ingredients necessary to carry out the process under vacuum. In order to avoid oxidation Oxford.

And loss of carbon - in the process under vacuum, which is comparable to our pieces.

Which is comparable with the growth of the workpiece to be hardened by. Install the thermostat on Maple Hill two lines on the surface and the core. The thermostat on Maple Hill is able to control the temperature.

Surface and the axis of the workpiece. Along the process of hardening. By this method we are able to; -

1. Dealing with stress, which occurs due to heat. While heating the workpiece. And cause less distortion

2. Prevention of structural Austen Knight. Is insufficient core and the dissolution of carbides in the structure Austen Knight too. By controlling the temperature of the structure Austen Knight axis.

3 application process Marquez Fishing for that. To prevent cracking and minimize distortion. Arising from the stress caused by heat. And structural In the case of parts with complex shapes.

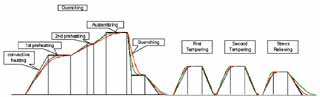

High-temperature annealing, tempering 3 times as a general rule of operation.

The tempering fires 1st to decompose Austen Knight residues. Which can not be avoided in high-carbon steel. Speed ??steel tools and ingredients

By baking the 2nd night we do to control them.

Has the desired hardness Baking night light 3 times is a stress relieve.

In order to prevent cracking. And deformation as a continuous process later.

|